Petrochemical

Petrochemical production facilities are among the most complex sites to monitor. Depending on the products and processes, facilities need to comply with various source-specific Environmental Protection Agency (EPA) air emissions.

ESC Spectrum’s Continuous Emissions Monitoring System (CEMS) solutions, including industry-leading Data Acquisition Systems (DAS) plus a wide variety of DAS and CEM systems, hardware, and services, are tailor-made to help petrochemical production plants meet their challenges.

DAS Solutions for Petrochemical Production

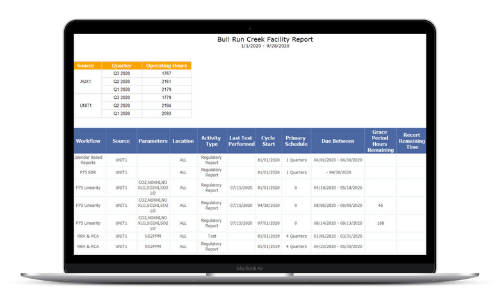

StackVision and Prism are the leading Continuous Emission Monitoring Data Acquisition Systems for facilities in various industries. Our DAS Software is used in over 3,100 air emission sources across the United States.

Both work seamlessly with the 8864 Data Controller to collect, monitor, QA, and report on emissions data from continuous monitoring systems accurately and reliably.

Our data acquisition systems are backed by 24/7/365 best-in-class customer support from a dedicated team of experts, online and in-person training. They are in continuous development to keep pace with industry changes.

Compliance Software for Petrochemical Production

QAInsight is air emissions compliance software that schedules, plans, and tracks a myriad of activities related to performing QA tests required by state and federal agencies.

FleXReports is a subscription-based software that helps facilities easily and securely export data from StackVision into Microsoft® Excel for maximum flexibility.

RATAView helps stack testers perform Relative Accuracy Test Audits (RATA) tests accurately and efficiently to meet complex regulations, including testing frequency, calculations, data gathering, and data retention requirements.

DAS Services for Petrochemical Production

The DASProtect support and maintenance services program ensures round-the-clock support, access to knowledge base articles, discounted services, training, software upgrades, and more.

Our DAS services teams are standing by to support the needs of power generation facilities, including:

CEMS Systems & Services for Petrochemical Production

We offer everything you need to keep your CEMS system healthy and in compliance.

With over five decades of experience building, testing, maintaining and repairing extractive, dilution, and in-situ CEMS systems to unique specifications, you can rely on us to meet the toughest CEMS challenges.

Our CEMS services support petrochemical production facilities with professional expertise.

Case Studies

StackVision™ Case Study: Petrochemical Plant

Learn how a Petrochemical plant used the StackVision Data Acquisition System for a +200K ROI by reducing Emergency Work Orders by 50%.

StackVision™ Case Study: Calumet Refinery

Learn how Calumet refinery used the StackVision DAS for flare monitoring and compliance with the Refinery Sector Rule (RSR).

StackVision™ Case Study: Delek-Tyler Refinery

Learn how the Delek-Tyler, TX refinery employed the StackVision Data Acquisition System to solve their complex needs and comply with RSR regulations.